INTRODUCTION

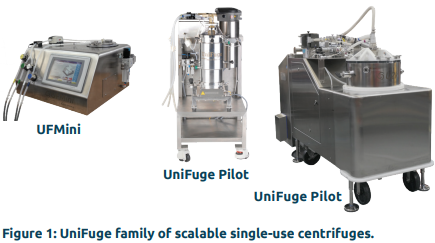

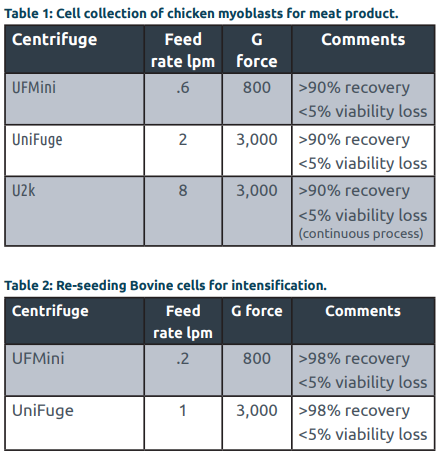

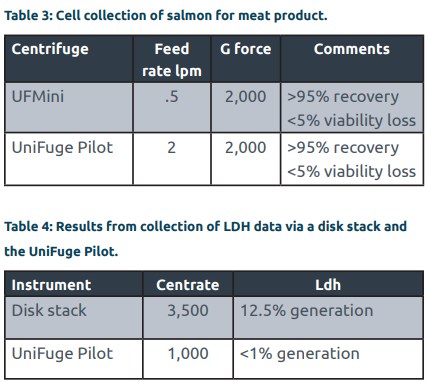

Cultivated meat cells can be collected with single-use centrifuges including the UFMini®, UniFuge® and U2k®. The tubular bowl centrifuge is very efficient from several perspectives. First, various cell densities are separated from the SUB broth with the elimination of bioreactor broth. Second, very high cell densities are collected with the cell slurry. Third, very low LDH values are common with the no-shear design. Last, animal cells can also be gently collected for re-seeding or cell banking by adjusting the g-force.

The UniFuge® family of single-use centrifuges scale from bench, pilot plant to commercial manufacturing.

THE CHALLENGE

The need for large-scale, yet economic collection of cultured animal cells is an increasingly important issue for the cellular agriculture industry. Generally, cell culture is engineered to produce the cells of interest by expanding animal cells (e.g. chicken, tuna, salmon, pig, bovine). Since the cell lines used are living organisms, they must be fed with a complex growth medium. Separation of the cells from the fermentation broth requires process development for efficient and gentle collection.

Cell harvesting or clarification of the harvested cells is of utmost importance. Process optimization in cellular agriculture is key to scale up to manufacturing scale. The UniFuge family of single-use centrifuges is demonstrated in this case study with scaling data.

MATERIALS AND METHODS

Materials and Instruments:

- Cells grown in bioreactors

- Singe use centrifuges: UFMini, Unifuge, U2k

Parameters:

- G-force – variable depending on cell lines and process

- Feed flow rate – variable Lpm

Method:

- Introduce feed broth to centrifuge

- Apply g-force

- Discharge bowl - various strategies

- Measure - cell slurry - biomass collection

THE RESULTS

CONCLUSION

The UniFuge family is an effective tool for the collection of animal cells used in the process of producing cultivated meats. The feed flow rate scales from small to large bioreactors. The low-shear inlet and non-shear discharge mechanism allows the elimination of cells and debris as seen in the LDH measurements or viability loss.

STAINLESS STEEL CENTRIFUGATION

In addition to the family of UniFuge single-use centrifuges, CARR Biosystems offers a full line of clean-in-place/sterilize-in-place stainless systems used in cultivated meat applications.

ABOUT THE UNIFUGE FAMILY

The UniFuge family provides low-shear separation, high-recovery performance, and fast processing times in three scalable models: UFMini, UniFuge Pilot, and U2K. With a variety of bowl sizes and flow rates ranging from 29 ml/min to 20 L/min, the UniFuge family of single-use separation systems offer both scalability and process efficiency in an aseptic closed system. The UniFuge Pilot was the industry pioneer in single-use centrifuge separation technologies. In 2021 CARR Biosystems released the UFMini to better support customers with a need for smaller scale processing using single-use technology

ABOUT CARR BIOSYSTEMS

Founded in 1993 in Medfield, Massachusetts, CARR Centritech introduced the PowerFuge and continued to develop advanced separation systems for the Life Sciences and Specialty Chemical markets with the ViaFuge, Centritech, and UniFuge models. In 2022, CARR Centritech transitioned to CARR Biosystems with continued emphasis on developing high-quality products to meet safety and quality standards throughout a variety of applications across the globe.