Stainless Steel Centrifuges

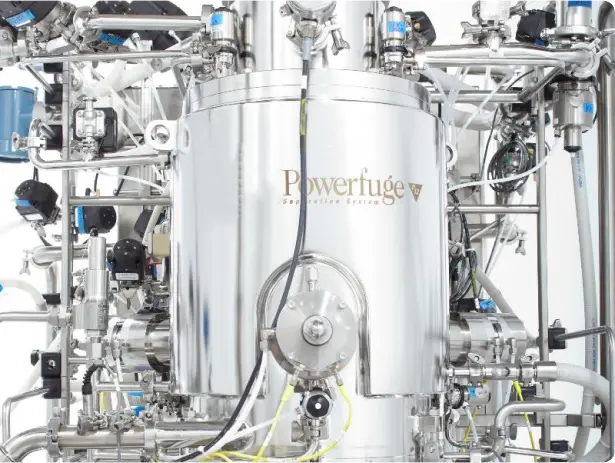

Optimize high-volume processing with our Clean-in-Place (CIP) and Sterilize-in-Place (SIP) stainless steel centrifuges. Choose from our specialized PowerFuge® and ViaFuge® families to achieve high product yield from even the most challenging separations.

Every Separation Met with High-Performance and Scalability

Power your bioprocessing workflows with stainless steel centrifuges designed for versatility, high yield, and maximum cell viability. The PowerFuge and ViaFuge work for a wide range of target biomolecules and allow you to scale up or down as needed.

Low-Shear, High-Performance Separations with Tubular Bowl Technology

Our stainless steel centrifuges are uniquely designed to preserve cell integrity and facilitate high processing speeds.

With PowerFuge and ViaFuge, you experience:

- Higher cell recovery with 98% cell viability

- Product yield up to 98% with minimal dilution

- High-yielding clarification of shear-sensitive products

- Low-shear media exchanges to wash and process live cells

- Minimal dwell time outside the bioreactor

PowerFuge Centrifuges: Designed for Bacteria, Fungi, Proteins, and Sub-Micron Particles

The PowerFuge family of stainless steel centrifuges is proven for the production of plasmid DNA, vaccines, plasma protein, cellular agriculture, and specialty chemicals.

- Particle size range

- G-forces up to 20,000 xg

- Flow rate from 250 ml/min to 1,700 L/hr

ViaFuge Centrifuges: Designed for Mammalian, Insect, and Plant Cells

The ViaFuge family delivers a typical cell viability of 98% or higher and yields up to 98%.

- Particle size range

- G-forces up to 10,000 xg

- Flow rate up to 2,400 L/hr

Technology Comparison

| Differentiation/Technology | PowerFuge | ViaFuge | Disc Stack Centrifuges | Depth Filtration | TFF |

|---|---|---|---|---|---|

| High G-force (Up to 20,000 x g) |  | No | No | No | No |

| Configurable for Closed Operations and Sterile |  |  |  | No |  |

| Minimizes Solid Waste |  |  |  | No | No |

| Viable Cell Recovery and Washing | No |  | No | No | No |

| Dewatering (Dry Cake) + Submicron Clarification |  | No | No | No | No |

| Auto Solid Discharge |  |  |  | No | No |

| Integrated Cooling Jackets |  |  |  | No | No |

| Power Fuge | Via Fuge | Disc Stack Centrifuges | Depth Filtration | TFF |

|---|---|---|---|---|

| High G-force (Up to 20,000 x g) | ||||

| No | No | No | No |

| Configurable for Closed Operations and Sterile | ||||

|  |  | No |  |

| Minimizes Solid Waste | ||||

|  |  | No | No |

| Viable Cell Recovery and Washing | ||||

| No |  | No | No | No |

| Dewatering (Dry Cake) + Submicron Clarification | ||||

| No | No | No | No |

| Auto Solid Discharge | ||||

|  |  | No | No |

| Integrated Cooling Jackets | ||||

|  |  | No | No |

Uniquely durable and scalable centrifuges for bacteria, fungi, proteins, and sub-micron particles

Stainless steel centrifuges for mammalian, insect, and plant cell separations

*Processing speeds are application dependent and may vary.

**Weights and dimensions are dependent on system configuration and options required.

Benefits of CARR Biosystems Single-Use Centrifuges

Performance

Maximize yield with our low-shear tubular bowl technology, enabling fast but gentle separation of your target product.

Scalability

Scale up or down with the PowerFuge and ViaFuge systems, available in various sizes to support small-scale development and large commercial volumes.

Versatility

Streamline the processing of various target biomolecules for high-throughput applications across diverse markets using our stainless steel centrifuges.

Quality

Preserve product quality and safety with stainless steel centrifuges built with CIP/SIP capabilities, ensuring cGMP-compliant separations.

Endorsements

See What People Are Saying About Our Stainless Steel Centrifuges

Looking for single-use centrifuges instead?

Our versatile single-use centrifuges are trusted by leading biopharmaceutical companies. Optimize resources throughout your bioprocessing workflow with UniFuge®.

EXPLORE OUR CELL PROCESSING PLATFORM

Featured Resources

Explore whitepapers, case studies, and more publications where labs achieved excellence with the PowerFuge and ViaFuge stainless steel centrifuges.

Frequently Asked Questions (FAQs) About Stainless Steel Centrifuges

What are the advantages of stainless steel centrifuges over single-use centrifuges?

- Durable and Long-lasting: Stainless steel centrifuges offer exceptional durability and a long lifespan, minimizing the need for frequent replacements and serving as a long-term solution.

- Processing Higher Volumes: Stainless steel centrifuges can consistently manage large-scale, high-volume processing, making them perfect for repetitive and continuous operations.

- Reduce Long-Term Costs: While the initial investment in stainless steel centrifuges is higher, the cost per use decreases over time, making them more cost-effective for extensive use.

What applications can CARR Biosystems stainless steel centrifuges be used for?

Our stainless steel centrifuges are versatile and suitable for various applications, including:

- Cell and gene therapy R&D

- Monoclonal antibody production

- Vaccine development

- Cultured meat applications

Their robust construction, high efficiency, and multiple-size availability make the PowerFuge and ViaFuge families ideal for pilot-scale and large-scale production across these diverse sectors.

Do the stainless steel centrifuges have tubular bowl technology?

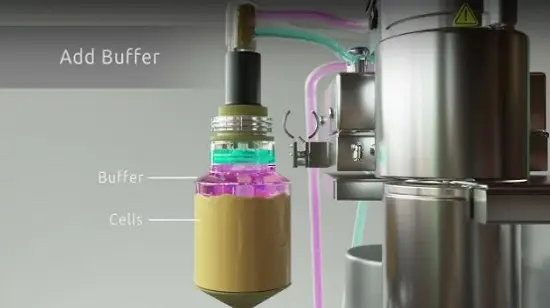

Our stainless steel centrifuges and UniFuge cell processing platform all use tubular bowl centrifugation. This technology works by balancing centrifugal forces and fluid flow rates so that solid particles (>4µm) are gently concentrated in the tubular bowl. The centrate — clarified media or buffer — flows into a collection chamber, and upon cycle completion, the concentrate — cells and/or other solids — is recovered with minimal loss and high cell viability, even over multiple cycles.

Stay Connected

Contact Us

Get in touch with a sales representative, request support or download our free white paper.

Contact Us