ViaFuge® V12: A Stainless Steel System for Large-Scale Cell Processing

Achieve 99% intact cell recovery and maximize yield with the ViaFuge V12. This system delivers efficient separation, reduces filtration needs by up to 90%, and through CIP/SIP supported automation, delivers consistent results at mid to large-scale while prioritizing low shear.

| Minimum Working Volume 9.6 L or 16.7 L | Flow Rate 30 L/min | G-force Up to 5,000 xg |

Benefits of CARR Biosystems ViaFuge V12

Viability

Maximize recovery of viable cells with gentle processing, specifically designed for shear-sensitive materials. Ideal for applications involving CHO, SF9, Vero, MRC5, and other mammalian cells.

Versatility

Easily adapt to diverse applications, including cell culture separations, media exchange, sterile operations, repeated batch processes, and process intensification, in both research and industrial settings.

Durability

Reduce downtime and maintenance costs with robust construction and high-quality materials designed for reliable performance and a longer operational lifespan.

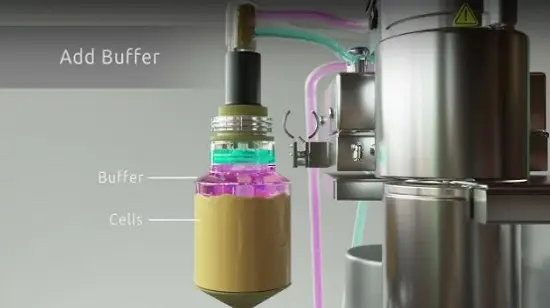

Closed Processing

Boost efficiency and protect cell viability with fully automated CIP/SIP cycles and PLC-controlled processes. The closed system minimizes contamination risk, maintains stable conditions, and reduces cell stress.

The ViaFuge V12 is a continuous-flow, industrial centrifuge designed for large-scale bioprocessing. Featuring a robust tubular bowl, it excels in automating solids removal to enhance efficiency while minimizing shear forces on cells. This system ensures high viability for delicate, shear-sensitive materials, making it ideal for demanding production environments where consistent, high-quality results are essential.

- Complete liquid/solid separations

- Full Clean-In-Place/Sterilize-In-Place (CIP/SIP)

- Validation guides

- Fully automated processes, including concentrate removal

- Integrated cooling jacket & spindle cooling unit

- Regulatory documentation available

- Closed processing system

Rec. Processing Volume | 3,000 L |

| Max Flow Rate | 30 L/min |

| Rotational Force | 500 - 5,000 xg |

| Max Concentrate Density | <1.5 g/ml |

| Weight (approx) | 1,116 - 1,889 kg (2,460 - 4,165 lbs) |

| Maximum Case Pressure | 6.9 bar (100 psi) |

| Programmable Logic Controllers (PLC) | Allen-Bradley® or Siemens® |

| Feed | Center for low-shear operation |

Electrical Requirements | 400 V/50 Hz or 480 V/60 Hz (configuration dependent) Spindle cooling unit: 230 V/50 Hz |

| Pneumatic | Instrument-quality air only, supplied at 80-100 psi |

Process Wetted Parts Construction

- USP Class VI components

- 316L stainless steel

- 17-4PH stainless steel

- Nitronic 60 stainless steel

- High-strength titanium alloy

- Teflon, silicone, ethylene propylene diene monomer (EPDM)

- O-rings and gaskets

- Stainless steel finish electropolished to 25 Ra

- Titanium alloy bowl tumbled finished to 25 Ra

Using tubular bowl technology, the feed is introduced through a stationary pipe to the center of the titanium-alloy bowl. Centrifugal forces gently concentrate viable cells along the bowl wall, preserving cell health. Once the bowl fills with cell concentrate, the simple manifold system and pump recover cells.

The ViaFuge V12 features:

- Service hoist

- Fully automated, intuitive software accessible through Allen-Bradley or Siemens HMI touchscreen 30.7 cm (12.1”)

- Designed to meet containment standards consistent with Biosafety Level 1 (BL1) and Biosafety Level 2 (BL2).

- Optional hazardous duty (Class 1, Div 1, Group C and D) and CE configurations available

- Designs available for SIP ASME- and PED-rated boundary and hazardous locations

- Closed processing system for solvents and hazardous materials

Endorsements

See What People Are Saying About Our Stainless Steel Centrifuges

Scale up or down with ViaFugeⓇ

Our ViaFuge family enables efficient liquid-solid separation with durable stainless steel construction. It is designed to handle delicate mammalian and insect cells, proteins, and other shear-sensitive materials from pilot to large-scale applications.

*Processing speeds are application dependent and may vary.

**Weights and dimensions are dependent on system configuration and options required.

Featured Resources

Frequently Asked Questions (FAQs)

What automated features does the ViaFuge V12 offer to enhance operational efficiency?

The ViaFuge V12 includes several automated features to enhance operational efficiency, such as CIP/SIP systems and PLC-controlled processes. These features reduce manual intervention, streamline cleaning and sterilization, and ensure consistent performance, making it highly suitable for demanding production environments.

How do the scalable bowl volumes of the ViaFuge V12 enhance its performance?

The large bowl volume of the ViaFuge V12, available in shallow (9.6 L) and deep (16.7 L) configurations, enhances its performance by allowing it to process larger volumes of material efficiently. This capacity is crucial for medium to large-scale production, where high throughput and consistent results are essential.

How does the ViaFuge V12 ensure high cell viability during the separation process?

The ViaFuge V12 ensures high cell viability by utilizing low-shear centrifugal forces within its tubular bowl, which gently separates cells from the liquid without causing damage. This design enables the system to achieve a 99% recovery of intact cells, making it ideal for applications where maintaining the integrity and viability of delicate cells is critical.

Stay Connected

Contact Us

Get in touch with a sales representative, request support or download our free white paper.

Contact Us