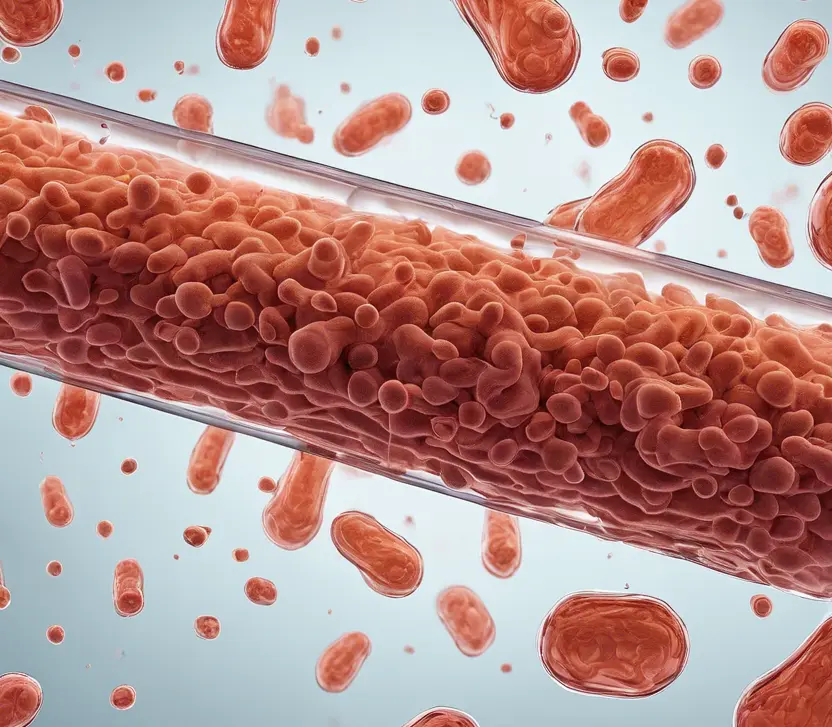

Several types of emerging cell-based and cell-derived products – including cell and gene therapies, synthetically cultured biologics, and laboratory-grown meats – are advancing our understanding of the separation process parameters that impact product quality and bioprocessing economics. During manufacturing, separation processes enable harvest, wash, concentration, and media exchange. These steps preserve valuable products such as cells and proteins while removing contaminants (spent media or reagents, cell debris, and particles). Centrifuges play a key role, as they can be tuned to balance separation efficiency while achieving other process goals such as product quality and processing speed.

Separation efficiency: The core goal

Separation efficiency can be defined as the percent of desired product that is recovered, or the percent of impurity removed. This article will explore the significance of separation efficiency and how tubular bowl centrifugation’s tunable critical process parameters – gravitational force and flow – can help developers find an operating window that offers the optimal balance between high separation efficiency, high productivity, and low shear forces.

Gravitational force (g-force)

When separating cells from contaminants or from the products they have produced, the cell type, size, and density determine the settling rate, which is the key factor influencing the separation efficiency of centrifuge-based technologies. During centrifugation, g-forces are used to accelerate the settling rate of the heavy phase, and flow rates and g-force are tuned to control separation efficiency and achieve CQA’s. G-force should be high enough to cause separation without negatively impacting cell health and be balanced with flow rate to achieve target separation efficiency.

Single-use tubular bowl centrifuges achieve over 95% recovery for various cell culture conditions and across a wide range of g-forces when properly sized and balanced with processing flow rates. Notably, single-use tubular bowl centrifuges are inherently low shear by design even as g-forces increase, allowing for increased processing speeds and flexibility. The low shear operation preserves cell health and viability throughout the separation process. In contrast, alternative large scale cell separation technologies such as conventional disc stack centrifuges have limited low-end g-force capabilities, only operating at high g-forces that can damage cells. Additionally, flow through a disc stack centrifuge occurs through small channels between the separation disks, subjecting cells to higher shear forces than are experienced in the open-flow paths found in tubular bowl centrifuges.

Flow rate

To achieve separation, tubular bowl centrifuges rely on achieving a high enough settling rate to carry solids to the capture surface before they exit with the clarified liquid. High flow rates can reduce capture efficiency if the residence time inside the bowl becomes too short for the solids to settle, while low flow rates primarily impact processing time. Operating at a higher flow rate and with the appropriate equipment scale (min/max processing volume) can lead to faster processing times, which may have a positive impact on product quality and/or economics.

Tunable cell handling for multiple applications

When harvesting monoclonal antibody cultures, relatively high g-forces are typically needed to best remove cells and cell-derived impurities. Alternatively, when handling sensitive cells that need to maintain optimal health and function for therapeutic purposes or further processing, it’s necessary to perform centrifugation at lower g-forces.

Tubular bowl centrifuges can compensate for lower g forces through flow rate modulation, where the flow rate is slowed down so that fluids spend more time in the centrifuge, providing more time for the cells to settle and be captured.

Achieving broader impact with tubular bowl centrifugation

Bioprocessing methods must be repeatable, reliable, and economical to allow cell and cell-derived products to enter the commercial market and reach patients and customers who need them.

For highly efficient separation of cell debris and impurities from bioprocessing streams, while safeguarding and thoroughly capturing valuable cell and cell-derived products, the tunability of flow and g-force in single-use tunable bowl centrifugation can shift in step with unique applications, preventing product damage and improving yield.