Stainless Steel Centrifuges

CIP and SIP-able Systems

CIP and SIP Stainless Steel Systems

Our reliable and robust stainless steel equipment addresses even the most challenging separations. Leading biopharmaceutical companies around the world rely on our machines to manufacture their licensed products. Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems can be used during product or batch changes to prevent contamination.

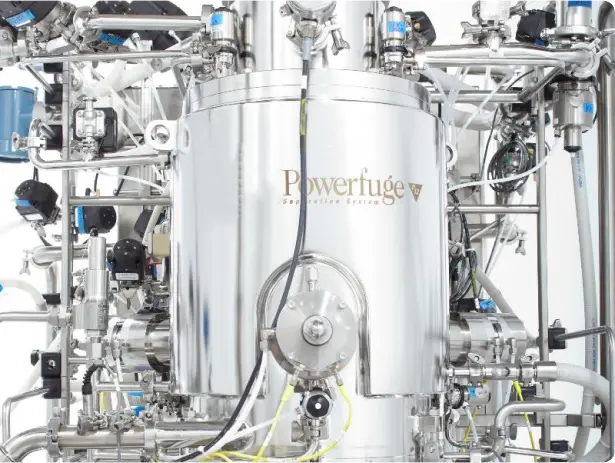

Powerfuge Family

- Designed for bacteria, fungi, proteins and sub-micron particles

- Proven for the production of plasmid DNA, vaccines, plasma protein, cellular agriculture and specialty chemicals

- G-forces up to 20,000 x g, the highest g force in the market

- Bowl volumes from 1.1 L to 36 L

- Flow rate from 250 ml/min to 1700 L/hr

- Solid-bowl centrifuges

- Automatic solid discharge

- SIP/CIP capabilities

- Hazardous duty option available

Viafuge Family

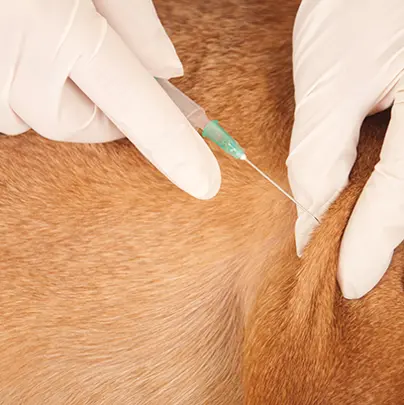

- Designed for mammalian, insect and plant cells

- Typical cell viability of 98% or higher

- Yield up to 98%

- G-forces up to 10,000 x g

- Bowl volumes from 1.4 L to 16.7 L

- Flow rate 2,400 L/hr

- Solid-bowl centrifuges

- Automatic centrate discharge

- SIP/CIP capabilities

Key Features

Advantages of Our Equipment

Our long history and deep expertise with pioneering separation technology allows us to deliver top-performing solutions through a reliable supply chain.

Performance

Our reliable and robust centrifuges address even the most challenging separations.

Scalability

Our equipment accommodates small process development volumes to very large commercial needs, allowing for seamless scale-up and scale-down.

Versatility

Our stainless steel centrifuges are designed to serve a variety of markets.

Stainless Steel Centrifuges

The Powerfuge® Family

Powerfuge centrifuges are well suited for separation of bacteria, fungi, proteins, and sub-micron particles. At the end of a run, compressed solids can be removed with minimal time and effort.

Viafuge ® V12

Clean-in-Place / Sterilize-in-Place System

The Viafuge® V12 is designed for fast, gentle medium- to large-scale cell harvesting and clarification. Capable of separating a wide variety of mammalian and insect cells with little to no damage, the Viafuge V12 offers high purity results with undetectable cell concentrations in clarified supernatant.

- Bowl capacity: 9.6 L or 16.7 L

- Flow rates up to 2400 L/hr for batches up to 2000 L

- Footprint: ~ 127 cm wide x 249 cm deep x 287 cm high (50” x 98 ” x 113”)

- Total weight ~ 1119 kg (2,460 lbs)

- Gentle cell harvesting and supernatant recovery

- scalableCan be scaled-down to smaller automated Pilot model

- Improved product processing

- Concentrated cells and supernatant can be recovered without breaking containment

- 20-fold concentration factor

Low-Shear Performance

The Viafuge V12’s unique design minimizes shear forces on cells, boasting a typical cell viability of 98% or higher and up to 98% yield.

Scalability

Processes developed on the Viafuge® Pilot can be seamlessly scaled to the Viafuge V12.

Features

- Bowl capacity: 9.6 L or 16.7 L

- Flow rates up to 2400 L/hr for batches up to 2000 L

- Variable speeds up to 5000 x g

- Sealed automatic operation

- Fully-automated operation

- Closed-system design with CIP/SIP

- cGMP construction

- ASME-rated designs available

- Flexible optimization

- Optional Hazardous Duty (Class 1, Div 1) CE configurations are available

- State-of-the-art manufacturing facility located in the United States

How It Works

Using an innovative design, the Viafuge V12 introduces feed through a stationary pipe, where it is accelerated to full rotational speed under low shear before entering the titanium-alloy bowl. Cells are then concentrated along a gentle path between the core and the bowl wall. The clarified supernatant is continuously discharged by gravity at atmospheric pressure. Periodically, the concentrated cells are automatically recovered from the Viafuge V12 for collection, and the cycle is repeated to process the remainder of the feed batch.

Automation and General Specifications

- Allen Bradley® or Siemens® PLC

- Allen Bradley® or Siemens® HMI touchscreen 30.7 cm (12.1”)

- Maximum case pressure (for cooling) 6.9 bar (100 psi)

Utility Requirements

- Power configuration: Three phase voltage supply:

- US: 230V/60 Hz, 20 A

- Europe: 200V/50 Hz, 20 A

- Japan: 200V/60 Hz/50 Hz, 20 A

- Optional: Others as needed

- Pneumatic: Clean, dry air supply 6 bar (90 psi) at 1 SLPM

Process Wetted Parts Construction

- USP Class VI components

- 316L Stainless Steel

- 17-4 PH Stainless Steel

- Nitronic 60 Stainless Steel

- Platinum cured silicone hoses

- EPDM elastomers

- Ti-6Al-4V Titanium

Stainless Steel Centrifuges Brochure

Stainless Steel Centrifuges Brochure

Stainless Steel Centrifuges

The Viafuge® Family

The Viafuge centrifuges are low-shear stainless steel systems designed for separation of mammalian, insect and plant cells with typical cell viability of 98% or higher.

Viafuge ® V12

Clean-in-Place / Sterilize-in-Place System

The Viafuge® V12 is designed for fast, gentle medium- to large-scale cell harvesting and clarification. Capable of separating a wide variety of mammalian and insect cells with little to no damage, the Viafuge V12 offers high purity results with undetectable cell concentrations in clarified supernatant.

- Bowl capacity: 9.6 L or 16.7 L

- Flow rates up to 2400 L/hr for batches up to 2000 L

- Footprint: ~ 127 cm wide x 249 cm deep x 287 cm high (50” x 98 ” x 113”)

- Total weight ~ 1119 kg (2,460 lbs)

- Gentle cell harvesting and supernatant recovery

- scalableCan be scaled-down to smaller automated Pilot model

- Improved product processing

- Concentrated cells and supernatant can be recovered without breaking containment

- 20-fold concentration factor

Low-Shear Performance

The Viafuge V12’s unique design minimizes shear forces on cells, boasting a typical cell viability of 98% or higher and up to 98% yield.

Scalability

Processes developed on the Viafuge® Pilot can be seamlessly scaled to the Viafuge V12.

Features

- Bowl capacity: 9.6 L or 16.7 L

- Flow rates up to 2400 L/hr for batches up to 2000 L

- Variable speeds up to 5000 x g

- Sealed automatic operation

- Fully-automated operation

- Closed-system design with CIP/SIP

- cGMP construction

- ASME-rated designs available

- Flexible optimization

- Optional Hazardous Duty (Class 1, Div 1) CE configurations are available

- State-of-the-art manufacturing facility located in the United States

How It Works

Using an innovative design, the Viafuge V12 introduces feed through a stationary pipe, where it is accelerated to full rotational speed under low shear before entering the titanium-alloy bowl. Cells are then concentrated along a gentle path between the core and the bowl wall. The clarified supernatant is continuously discharged by gravity at atmospheric pressure. Periodically, the concentrated cells are automatically recovered from the Viafuge V12 for collection, and the cycle is repeated to process the remainder of the feed batch.

Automation and General Specifications

- Allen Bradley® or Siemens® PLC

- Allen Bradley® or Siemens® HMI touchscreen 30.7 cm (12.1”)

- Maximum case pressure (for cooling) 6.9 bar (100 psi)

Utility Requirements

- Power configuration: Three phase voltage supply:

- US: 230V/60 Hz, 20 A

- Europe: 200V/50 Hz, 20 A

- Japan: 200V/60 Hz/50 Hz, 20 A

- Optional: Others as needed

- Pneumatic: Clean, dry air supply 6 bar (90 psi) at 1 SLPM

Process Wetted Parts Construction

- USP Class VI components

- 316L Stainless Steel

- 17-4 PH Stainless Steel

- Nitronic 60 Stainless Steel

- Platinum cured silicone hoses

- EPDM elastomers

- Ti-6Al-4V Titanium

Stainless Steel Centrifuges Brochure

Stainless Steel Centrifuges Brochure

Endorsements

See What People Are Saying About Our Equipment

Stay Connected

Contact Us

Get in touch with a sales representative, request support or download our free white paper.

Contact Us

Leave a commentOrder by

Newest on top Oldest on top