INTRODUCTION

Gene-based therapies and vaccines commonly rely on the use of viral vectors to deliver their payload to patients’ cells, and HEK293 cell culture has become the top choice for producing these therapeutic viral vectors. Conventionally, depth filtration is performed primarily to clarify these cultures.

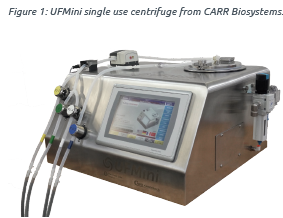

In this case study, we share results from a series of proof-of-concept studies that first establish optimal parameters for using the UFMini® single-use centrifuge to collect viral titer from HEK293 cells and then evaluate the UFMini’s performance in comparison to traditional depth filtration methods. The UFMini is a single-use, semi-continuous centrifuge designed for primary clarification of mammalian cell cultures.

THE CHALLENGE

As new therapies and vaccines progress from research & development into production for the clinic, bioprocessing development engineers must prioritize the ability to perform high-throughput clarification of HEK293 cell cultures without sacrificing quality and titer of the viral vector collected. With today’s bioreactors capable of producing high-density cell cultures at volumes up to 2000L or more, manufacturers that rely on depth filtration alone to clarify cultures have had to keep pace by using a higher number of filters to capture viral vectors from each production batch.

Depth filtration, used to separate biological debris and viral vector from transfected and lysed HEK293 cells, is a labor-intensive process that takes up a significant amount of space at the bench and in the stockroom, relies on having a large quantity of one-time-use filters on hand, generates substantial amounts of hazardous waste for disposal, and requires heavy water usage for repeated flushing. The more filters it takes to remove viral titer from a culture, the lower the viral titer is likely to be, with viral vector getting stuck and lost within the numerous filters which are then thrown away.

THE SOLUTION

To evaluate how well the UFMini could improve primary clarification of HEK293 cell culture, we teamed up with a customer partner to perform a series of experiments. Our goal was to identify the optimal UFMini flow rate and g-force settings to improve clarification and reduce the number of times the culture was run through filtration in comparison to conventional benchmarks. Together, we used the UFMini to clarify HEK293 cells at various g forces (2000-4000g) and feed flow rates (200-600ml per minute).

Our team measured titer and throughput after cleaning up 1L batch of HEK293 culture containing viral vectors using the UFMini, seeking to identify the optimal combination of forces and flow rate to increase titer and flow rate. We determined the ideal UFMini settings to 4000 g-forces with a flow of 226ml per minute, an automated process that took 10 mins to clarify the 1L batch of culture. In a side-by-side comparison of the UFMini against depth filtration alone, the UFMini increased throughput from 46L/m2 to 59L/m2 and ultimately boosted yield from 37 percent to 54 percent.

RESULTS

Compared to depth filtration alone, the UFMini removed bulk solids using 28 percent less filter surface area. After performing secondary filtration, the UFMini achieved a 46 percent increase in viral titer.

DISCUSSION

The results of these studies indicate that using the UFMini to clarify a batch of lysed UFMini cell culture drastically increased final viral titer and cut down on the time and material cost of the clarification and viral vector collection process. In contrast, using depth filtration alone reduced the overall product yield; this in addition to its labor-intensiveness and material costs could be problematic for teams tasked with efficiently moving gene-based therapies from small-batch R&D into manufacturing at scale.

ABOUT THE UNIFUGE FAMILY

The UniFuge family provides low-shear separation, high-recovery performance, and fast processing times in three scalable models: UFMini, UniFuge Pilot, and U2k. With a variety of bowl sizes and flow rates ranging from 29 ml/min to 20 L/min, the UniFuge family of single-use separation systems offer both scalability and process efficiency in an aseptic closed system. The UniFuge Pilot was the industry pioneer in single-use centrifuge separation technologies. In 2021 CARR Biosystems released the UFMini to better support customers with a need for smaller scale processing using single-use technology.