Single-Use Centrifuges

High-Yield Cell Processing from the Lab, to the Clinic, and Beyond

With the UniFuge platform of single-use centrifuges, you can isolate cells with up to 98% product recovery. Our versatile, fully automated cell processing platform safeguards cell viability and product quality for your cell-based and extracellular products.

Contact us to learn moreBenefits of CARR Biosystems Single-Use Centrifuges

Performance

Our proven low-shear technology boasts a typical cell viability of 98% or higher and up to 98% yield.

Scalability

Our equipment can be used from development to commercial licensure and across different reactor volumes.

Ease of Use

Our machines are easy to install and simple to operate.

Small Footprint

Our machines are easy to install and simple to operate.Our UniFuge centrifuges have a small footprint.

High-Yield Cell Processing From Research to cGMP Manufacturing

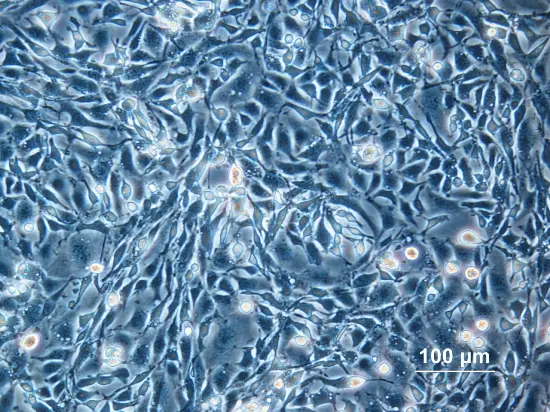

UniFuge single-use systems are purposefully designed for application throughout bioprocessing workflows. UniFuge is high-separation performance, versatile, and scalable, allowing you to optimize product development and process economics early and continuously. Match cell culture volume and resource requirements during early-stage development with the UFMicro®, then scale up your experiments for cGMP manufacturing with Pilot and U2K®.

Maximize Yield With Low-Shear and Faster Processing Speeds

Our single-use centrifuges use tubular bowl technology that enable fast cell processing speeds while minimizing shear forces and maintaining separation efficiency.

- Higher cell recovery with >95% cell viability during separation

- Product yield up to >95% with minimal dilution

- High-yielding clarification of shear-sensitive products

- Low-shear media exchanges to wash and process live cells

- Minimal dwell time outside the bioreactor

Whether you need to isolate cell-based therapies, clarify large molecules, or harvest cultured meat products - UniFuge will deliver.

Designed for Versatility and Reliability

Use UniFuge at the beginning, middle, or end of your cell processing workflow for cell enrichment, media change, or concentrating cell suspensions for product formulation and filling. With over 25 years of expertise in centrifugal separation, we designed the UniFuge cell processing platform to meet the demands of modern bioprocessing.

- Proven performance in cell concentration, washing, and harvesting, formulation, media exchange or perfusion, primary clarification, supernatant recovery, and more

- Tunable for cell therapy, gene therapy, mAbs, vaccines, cultured meat products

- Easy to install and simple to operate for diverse applications

Scale Seamlessly Through GMP Operations

Match the scale of your processing requirements with a UniFuge cell processing family product. With flexible processing volumes the UniFuge will scale with your needs from development through commercialization - scale-up or scale-out.

- Four single-use centrifuges with a range of process volumes from 70 mL to >2000 L

- Lower consumable usage via improved capacity utilization and one-step depth filtration

- Fully automated with the option to run in manual mode

- Set up and change over in under 15 min

- cGMP-compliant 21 CFR Part 11 data trail

Our UniFuge Platform

UniFuge single-use centrifuges have a variable g-force up to 4,000 x g. The pre-sterilized single-use modules are ready-to-use, and built to optimize.

*Processing speeds are application dependent and may vary.

**Weights and dimensions are dependent on system configuration and options required.

Endorsements

See What People Are Saying About Unifuge

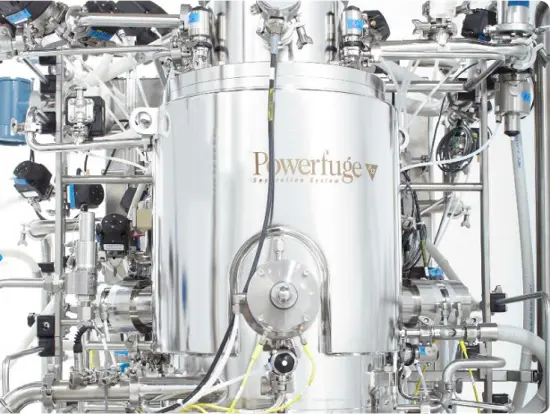

Looking for Multi-Use Centrifuges Instead?

Our selection of stainless steel centrifuges are trusted by leading biopharmaceutical companies. Isolate products ranging from submicron particles to mammalian cells with the PowerFuge and ViaFuge centrifuge families.

Explore Stainless Steel Models

Featured Resources

Explore whitepapers, case studies, and publications where UniFuge single-use centrifuges helped teams achieve excellence.

Frequently Asked Questions (FAQs) About Single-Use Centrifuges

How do single-use centrifuges minimize cell loss?

Our single-use centrifuge systems use tubular bowl technology to minimize cell loss through gentle handling, rapid processing, and precise media exchange in a closed system.

Can single-use centrifuges handle high-volume processing?

Yes, our single-use centrifuges are designed to handle various processing volumes. For example, the U2K® model can process volumes up to 2000+ liters, making it suitable for large-scale biopharmaceutical production. Our UFMicro and UFMini models make it easy to scale down according to your needs.

How do single-use centrifuges contribute to GMP compliance?

Single-use centrifuges support GMP compliance by offering repeatable and automated operations. They have options for manual control, rapid setup, and changeover times under 15 minutes. They also provide a comprehensive data trail that meets the requirements of 21 CFR Part 11, enabling regulatory compliance and traceability.

What are the advantages of single-use centrifuges over reusable sample models?

- Faster setup and change-over

- Lower contamination risk due to disposable components

- Reduced operational costs for maintenance, labor, and cleaning

Stay Connected

Contact Us

Get in touch with a sales representative, request support or download our free white paper.

Contact Us