Higher recovery, fewer filters, and scalable performance for modern mAb processes.

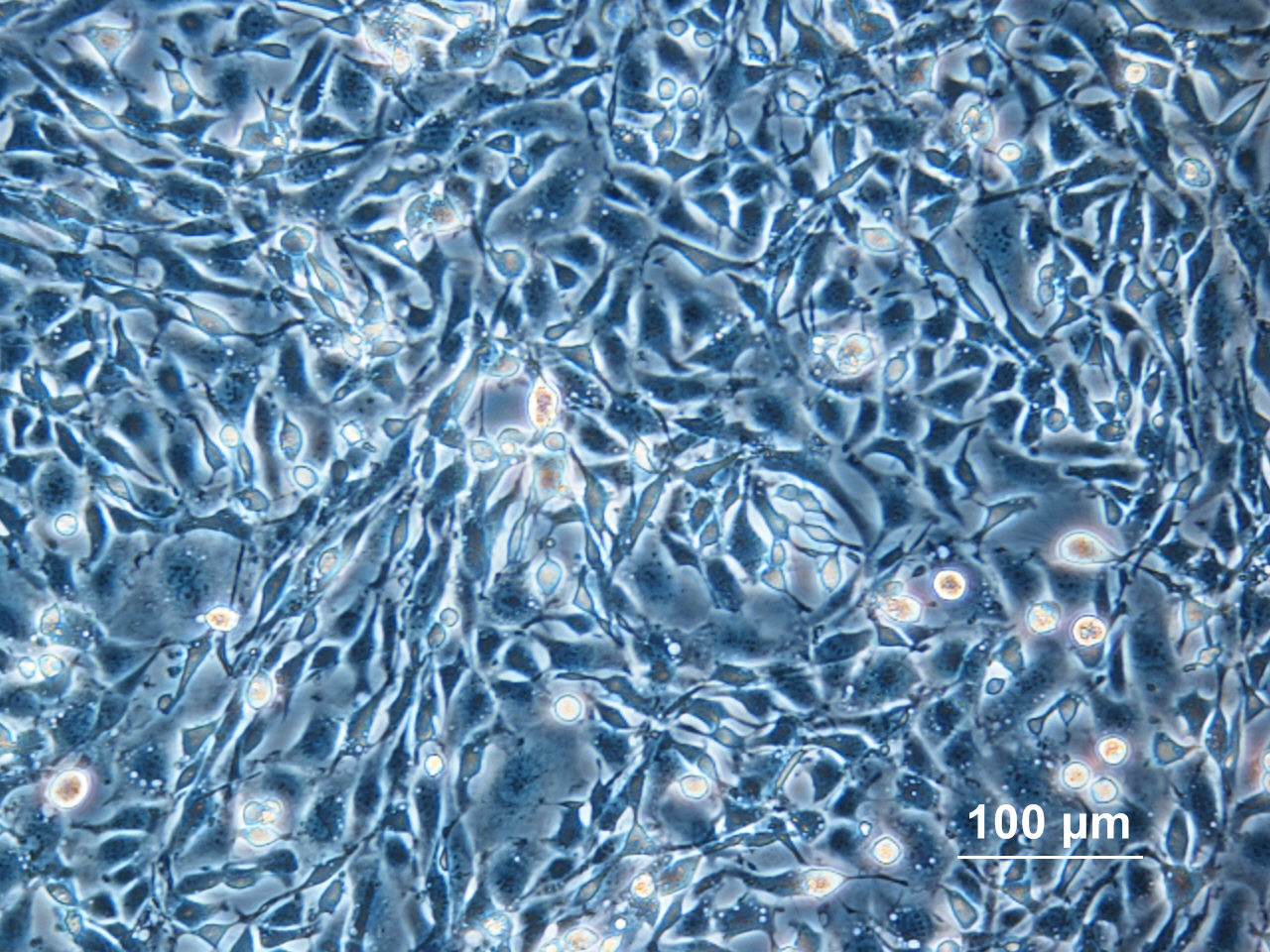

Clarification in production of monoclonal antibodies is often treated as a solved step in monoclonal antibody (mAb) production, yet 5–15% of the product can still be lost to depth filters. That’s weeks of upstream work, including cell growth, feeding, and monitoring, all vanishing into filter cakes and hold-up volumes.

As upstream titers climb and batch sizes increase, those losses add up to more buffer, more time, and higher costs. The question is simple: how much value disappears at clarification, and how to get it back?

Depth Filtration: Losses, oversizing, and operational burden

Depth filters clarify mAb cultures, but not without costs. Even in well-run processes, 5–10% of the product is lost, sometimes climbing to 15% in high-intensity runs. Chase buffers can push recovery higher, but they also inflate buffer use, lengthen in-suite time, and overload Protein A columns downstream.

At commercial scale, teams avoid problems by massively oversizing filtration area, often building in 20–40% extra capacity as a safety factor. A 2000-liter bioreactor harvest can call for 60 or more cartridges. That decision drives a heavy operational load:

Storage and transfer: QA receiving and incoming inspection, warehousing, staging in intermediate storage, and material ingress procedures (including wipe-down for transfer through air locks), which often involve handling 60+ cartridges for a 2000L run.

Setup: unpacking, loading into holders, and pre-flushing with hundreds to thousands of liters of WFI and buffer.

In-process: operating oversized filter trains, buffer chases to recover product, and occasional blow-down steps.

Teardown and disposal: sanitizing with NaOH, flushing caustics, reducing liquid waste by blow-down, and disposing of heavy, wet cartridges, all while maintaining cleanroom standards and ISO class.

Documentation and traceability: logging each filter’s lot number, expiration date, and sterilization status, and recording these details in batch records — a significant workload for operations and QA.

Every step adds labor, buffer, and cleanroom occupancy. What looks like a routine clarification in production of monoclonal antibodies can quietly consume a surprising share of facility time and cost. That’s why many teams are redefining what “good” clarification looks like.

A smarter mAb clarification: Less buffer, smaller footprint

An improved harvest process doesn’t just recover more antibodies. It also simplifies everything around it. The goal is to reduce filter trains, shrink buffer volumes, ease facility footprint, and minimize manual oversight.

With centrifugation as the primary clarification step, buffer use can be modeled at a fraction of what’s required to flush dozens of depth filters. Facility space also improves: instead of racks of cartridges, pumps, and tangled tubing, the setup is cleaner and easier to manage.

UniFuge®: Higher recovery, fewer filters

UniFuge® shifts the role of depth filters from being the workhorse to a secondary polishing step. Centrifugation handles the bulk of clarification, leaving a smaller, cleaner load for downstream filters. Instead of racks of cartridges, teams handle a fraction of the filtration area, cutting back on buffer, handling, and teardown.

Designed for low-shear operation, UniFuge protects product quality while reducing impurities that can leach from dense filter cakes. Its closed, single-use design lowers contamination risk and removes the need for cleaning validation, while recipe-driven automation standardizes operation across batches.

The platform scales seamlessly from development to commercial runs, using the same bowl design and control logic across models. In practice, that translates into:

Higher recovery: Recover more antibodies, often achieving yields above 90% compared to filter-heavy workflows.

Fewer filters downstream: Reduce the size of filter trains, which cuts flush volumes, labor, and cleanroom time.

Shorter suite occupancy: Shrink the time burden across the entire workflow, from setup and pre-flush through teardown and disposal.

Automated, recipe-driven execution: Standardize operation with automation that delivers consistent performance at any scale.

The result is a clarification that protects the batch you’ve already earned.

Keep more of the antibodies you’ve already made

Depth filtration has been the default for clarification in production of monoclonal antibodies, but it comes with hidden costs in product loss, buffer, and time. As upstream processes intensify, those costs become increasingly difficult to ignore.

By shifting the heavy lifting to UniFuge, you reduce filter dependence, recover more antibodies, and simplify operations from start to finish. For teams scaling modern CHO processes, UniFuge enables them to retain more of every batch, ultimately achieving balance between upstream and downstream performance.

Discover how UniFuge streamlines mAb clarification, achieving higher recovery and reduced filter usage.