When equipment does too little—and what to do about it

The cost of idle systems

Cleanroom space is premium real estate, and most teams are working with less of it than they’d like. But many facilities are still filled with systems that do one thing, once per batch, then sit idle. That creates a hidden cost: unused equipment consumes floor space, validation effort, and scheduling attention without delivering consistent value.

If a system only supports one operation and can’t flex across workflows, its footprint is hard to justify, especially when capacity is tight and every addition requires a trade-off.

Single-use systems = single-use space

Idle time = wasted capacity

Rigid workflows = capped process efficiency

Versatility as a capital efficiency strategy

When space is limited and workflows evolve, versatility becomes a design requirement. Teams don’t need a dedicated system for every step. They need equipment that can adapt, supporting multiple operations and cell types without added retraining, infrastructure, or duplicate qualification efforts.

This isn’t hypothetical. We’ve seen teams use a single UniFuge system to support multiple unit ops—harvest, wash, buffer exchange, pre-formulation—and in some cases, serve multiple bioreactors, depending on scheduling and batch design.

What versatility looks like in practice:

Multi-step capability: one system handles harvest, wash, buffer exchange, and more

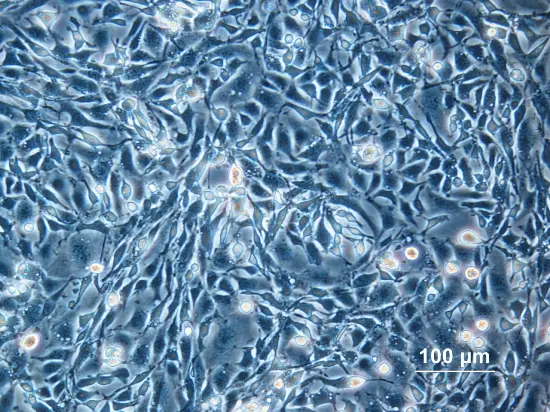

Cross-application compatibility: iPSC, MSC, NK, CAR-T—all on one platform

Reduced qualification burden: fewer protocols to qualify

Flexible scheduling: same equipment, different roles, as needs change

Cleanrooms are like toolboxes: limited and valuable. A single-function system is like dedicating half that toolbox to a wrench you only use once a week. What you need is a Swiss Army knife. |

All-in-one systems can limit agility

All-in-one systems promise simplicity, but in practice, they often create bottlenecks. In workflows where each batch takes days or even weeks to complete, a fully integrated system can tie up critical functionality far longer than necessary. We’ve seen systems used for autologous therapies that lock up selection, washing, formulation, and even incubation in a single unit, effectively putting the brakes on any shared use or flexibility.

The challenge isn’t integration—it’s rigidity. These systems can’t be reconfigured to support other steps or rerouted for different workflows. Once they’re running, they’re unavailable.

The more innovative alternative: modular, not constrained

Instead of bundling every step into a fixed box, process teams are looking for modular systems that plug into multiple points in the workflow—and are available when needed. With modular platforms, you get the best of both worlds:

The reliability of closed-loop operation

The ability to avoid scheduling conflicts and maximize equipment utilization

Over-consolidation leads to underutilization. You want systems that are connected, not constrained. |

Planning for space, scale, and process optimization

We’re seeing a clear shift in how process teams think about capital equipment—not just in what they buy but also in how they deploy it. The old model of buying step-specific tools is giving way to more agile, modular setups that allow for shared use, smoother scheduling, and fewer cleanroom trade-offs.

One thing we see more and more:

Customers are teaching us new ways to apply the system across their workflows. We’re supporting them with process expertise, sizing calculators, and a versatile and easy-to-implement platform.

That means platforms that can support multiple steps without needing additional space, systems that can move with the process as it scales, and tools that don’t become obsolete with the next protocol update.

Scalability matters, but adaptability is what keeps a manufacturing strategy relevant. |

In practice, that means using a single platform to handle multiple process stages or designing a cleanroom layout where equipment can shift roles depending on the day’s needs. Fewer systems, fewer silos, more adaptability.

UniFuge® as a versatile, modular platform

UniFuge® delivers the versatility modern cell therapy facilities require. More than a harvesting tool, UniFuge is a versatile system that can handle harvest, washing, buffer exchange, and pre-formulation, all within a closed, low-shear environment. That flexibility reduces equipment count, validation burden, and cleanroom congestion while maximizing process performance and protecting cell quality.

Equally important, UniFuge integrates seamlessly with upstream and downstream operations. There’s no need for custom interfaces or workarounds to transition between steps. One platform, multiple roles with no added complexity.

Built for shared use and cleanroom efficiency:

Integrates easily with upstream bioreactors and downstream formulation

Supports compliant workflows without revalidation between steps

Maintains process continuity from UFMini® to U2K®, with consistent mechanics

“We’ve seen customers use UniFuge to support multiple steps across workflows—without introducing new equipment or requalifying existing setups.” |

In facilities where space is limited and reconfigurable systems are essential, versatile, tunable platforms like UniFuge allow teams to do more with less, without being locked into rigid, all-in-one systems.

Capital efficiency starts with a smarter use of space

Cleanroom efficiency depends as much on how equipment is used as on how fast it performs. When space is limited and workflows are constantly evolving, the most valuable systems aren’t overloaded with features—they’re versatile, adaptable, and built to do multiple jobs well.

At CARR, we believe that capital efficiency comes from investing in equipment that evolves with your process instead of limiting it. UniFuge helps teams adapt, scale, and simplify without adding complexity.

Let’s talk about how we can help you get more from the space you already have.