Why many cell washing workflows still fall short

Cell washing and formulating therapeutic cells present unique process challenges. These steps must be efficient, reproducible, and gentle—while also meeting strict quality requirements and achieving regulatory compliance.

Incomplete removal of media components: Residual serum proteins, cytokines, and waste metabolites can interfere with downstream applications, such as gene editing, cryopreservation, or pre-formulation. High-efficiency buffer exchange is critical to ensure product consistency and safety

Manual and open handling steps: Open workflows that involve centrifuge tubes, biosafety cabinets, or manual buffer exchanges increase contamination risk and operator variability. They are also difficult to scale or validate for GMP environments.

Limited throughput and processing bottlenecks: Manual and single-sample workflows slow batch processing, increase time-in-suite, and create bottlenecks as production scales. Efficient, automated systems are essential to keep up with clinical and commercial demand.

What high-performing wash and pre-formulation systems do differently

To improve consistency, reduce risk, and preserve cell integrity, cell washing and pre-formulation systems must be purpose-built for therapeutic applications—not adapted from research tools or time-intensive filtration workflows. The following design elements are critical to achieving high-performance results at clinical and commercial scales.

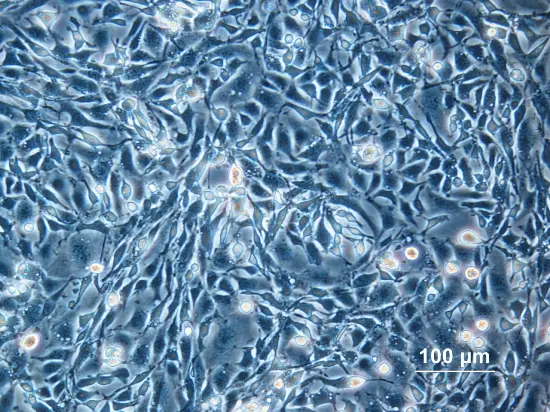

Low shear, high recovery

Minimizing mechanical stress is essential for preserving cell quality. Systems like the UniFuge® operate at moderate G-forces and controlled flow rates. These conditions reduce shear and turbulence, helping to protect cell health throughout washing operations.

- In UniFuge systems, typical outcomes include >90% recovery and <5% viability loss, even with shear-sensitive cell types such as iPSCs, MSCs, NK cells, and CAR-T cells.

Automated, high-efficiency buffer exchange

Manual buffer exchange introduces variation and inefficiency. Automated systems that incorporate buffer rinses and resuspension functions enable multiple exchanges within a single, closed cycle. This approach consistently achieves high contaminant removal without relying on excessive buffer volumes, improving both throughput and reproducibility. It also supports smoother tech transfer by standardizing buffer exchange protocols across scales and production sites.

- UniFuge systems routinely achieve buffer exchange efficiency above 90%, without the high volumes or manual steps

How to safely introduce cryoprotectants without compromising viability or system integrity

Cryopreservation workflows often involve the use of cryoprotectants—such as dimethyl sulfoxide (DMSO) —which require careful handling. While DMSO is effective at preserving cells during freezing, it is cytotoxic and can degrade system components if not managed properly.

Pre-formulation flexibility

In many workflows, pre-formulation buffers—such as cryopreservation media or excipients—are introduced after final washing and resuspension to target cell concentration and streamline processing. Systems like UniFuge support this by enabling direct buffer integration within the wash protocol, allowing teams to prepare concentrated, cell suspensions ready for pre-formulation, vialing, bag fill, or storage. By integrating washing and final buffer exchange in a single closed system, platforms like UniFuge reduce the need for separate mixing vessels or transfer steps.

Four signs your cell washing and pre-formulation workflow needs attention

The wash and pre-formulation phase is often under-analyzed—but evaluating this step with clear performance and compliance goals can reveal opportunities to improve consistency, reduce risk, and streamline downstream operations.

Key questions to assess your current approach:

- Are you achieving sufficient wash efficiency without excessive buffer volume?

Poor exchange efficiency can leave behind residual proteins or salts that impact cell health or downstream performance. - What is your current viable cell recovery during wash and pre-formulation?

Even small losses can reduce available therapeutic dose and lower overall process yield. - Is your workflow automated and designed for reliable, GMP-scale manufacturing?

Manual steps introduce variability and make it harder to ensure consistent, reproducible processing as batch volumes increase. - Are you achieving target cell concentrations during resuspension—and using the right technology for your scale?

Matching buffer volumes and processing capabilities to your batch size is critical, whether you're working with UF Micro, UF Mini, or UF Pilot modules.

Small changes in this step can have an outsized impact—starting with a clear understanding of where your current workflow may be underperforming.

Build your process on a scalable cell washing and pre-formulation platform – and protect your product

Cell washing and pre-formulation shape the final quality and consistency of a cell therapy product—whether working with iPSCs, MSCs, NK cells, CAR-T cells, or other allogeneic immune cell types. Optimizing this step means more than protecting viability—it streamlines operations, reduces risk, and supports seamless integration with downstream processes.

Learn how UniFuge® supports scalable, closed, and efficient solutions for cell washing and pre-formulation.