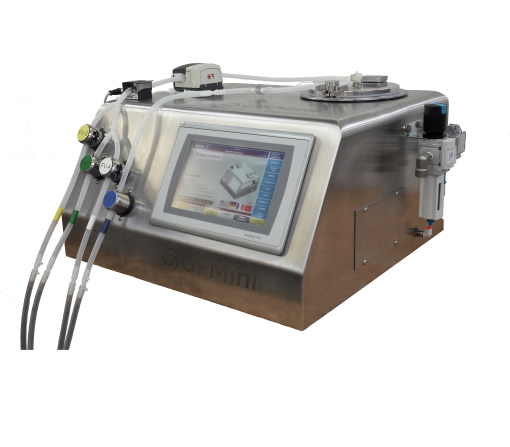

This study shares data from an MSC-therapeutics company that evaluated the UFMini® against their current process, with results provided to CARR Biosystems for publication.

Abstract

Mesenchymal stem cells (MSCs) are widely used in cell therapy for their immunomodulatory properties and scalability across human and veterinary applications. As these therapies advance toward clinical and commercial manufacturing, developing cell processes that are repeatable and maintain cell health are critical to achieving clinical success. Low recovery is often driven by a drop in cell viability which can result from excessive shear stress, prolonged exposure outside controlled environments, and inefficient separation methods during cell processing. This case study showcases how a cell therapy developer used the UniFuge® system to consistently achieve greater than 90% cell recovery and less than 5% cell viability loss, representing improvements of 25% and 15%, respectively, outperforming the incumbent method and meeting all user-defined performance targets. By improving viability and ultimately recovery, the UniFuge system ensures cells are ready for downstream operations.

This study demonstrates the use of the UniFuge Mini (UFMini®) Single-Use Tubular Bowl Centrifuge as a closed, automated, and scalable solution for MSC harvest, wash, and concentration. The study assessed the UFMini’s performance across six independent runs with varying input volumes and flow rates. The low-shear, closed-system design enabled reproducible outcomes and efficient processing times, with 4-liter batches completed in under 30 minutes. These results support its integration into MSC workflows and its potential to streamline the transition from development to commercial-scale MSC manufacturing.

Introduction

Mesenchymal stem cells (MSCs) have emerged as a promising cell type in regenerative medicine and cell therapy due to their rapid expansion kinetics, immunomodulatory properties, and versatility across both human and veterinary medicine. Clinically, MSCs are being investigated and used in therapies for conditions such as osteoarthritis, Parkinson’s Disease, and Crohn’s Disease.

As MSC-based therapies progress toward clinical and commercial implementation, high-yield and repeatable downstream processing strategies are critical for scalable and cost-effective commercialization. At the same time, preserving cell health and potency is essential to ensure consistent clinical outcomes including therapeutic function, persistence, and resistance to exhaustion. Critical process steps such as media removal, buffer exchange, and volume reduction not only affect recovery and viability, but are challenged by scalability and integration with upstream bioreactor systems as well as downstream fill-finish operations. These operations play a significant role in determining overall manufacturing efficiency, cost-effectiveness, and regulatory compliance.

However, conventional harvesting often falls short of performance expectations. In this study, the incumbent process technology consistently underperformed relative to their defined recovery and viability targets, prompting evaluation of alternative separation technologies capable of delivering higher yield and consistency.

This study, conducted in collaboration with a cell therapy developer, evaluates the UFMini, single-use tubular bowl centrifuge as a closed, automated, and scalable platform for MSC harvest, wash, and concentration. The UFMini was tested across a range of input volumes and cell densities to assess its ability to consistently deliver greater than 90% recovery and less than 5% viability loss, surpassing incumbent technologies while maintaining process reproducibility.

By comparing performance across six independent runs, this study highlights how the UFMini’s low-shear, closed system design repeatably exceeded target criteria. These results demonstrate the platform’s ease of use, making it simple to adopt and integrate during early development. Its automated, repeatable workflows help eliminate variability in experimental data. The system is designed for scalability, allowing teams to transition to larger manufacturing platforms without late-stage tech transfers that risk altering cell characteristics supporting consistent dose reliability, improved throughput, and economic viability across both human and veterinary MSC-based therapies.

Study Objectives

To effectively compare single-use tubular bowl centrifugation to conventional separation methods, the cell therapy developer defined specific performance targets, referenced in Table 1, for MSC harvest, wash, and concentrations. These criteria were used to assess whether the UFMini could meet the operational and quality requirement necessary for downstream MSC processing at scale.

10db1bda-660a-4ffd-8d1b-b96bf79c2758.png?sfvrsn=ed49817f_1)

Table 1: Target Objectives with UFMini Study

Materials and Methods

Cell Line and Culture Conditions

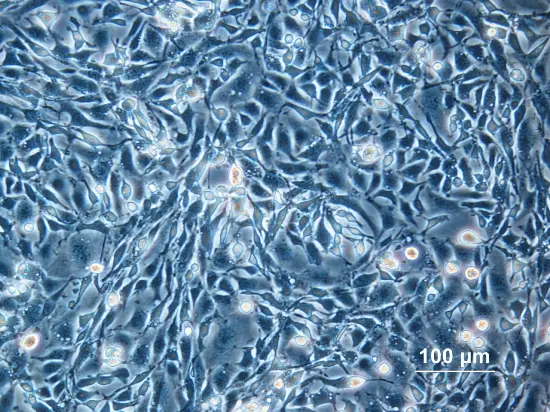

Animal-derived mesenchymal stem cells (MSCs), 15 microns in diameter, were cultured for 14-days using pre-established protocols for MSC expression, expansion, and harvest.

Experimental Design

The UFMini and module were used to wash and concentrate MSCs. Six independent runs were conducted using input volumes ranging from 1 to 5 liters. The harvest, wash, and concentrate protocol included the following steps:

- Prefill the bowl with fresh medium,

- MSC harvest separation at various g and various flow rates,

- Washing of the pelleted cells with fresh medium,

- Multiple cell-resuspension cycles for enhanced recovery,

- Discharge of concentrated, washed MSC for collection at various flow rates,

- Final bowl chase with medium to maximize yield recovery.

Two washing protocols were tested to evaluate recovery and washing efficiency under different conditions.

Analytical Techniques

Cell counts and viability were measured during feed, waste, and final product stages of the process using the NucleoCounter® NC-200™ and Via1-Cassette™. Results were used to evaluate viable cell recovery and viability loss across all runs, as well as assess consistency across varying input volumes and flow rates.

Results

Recovery and Viability Performance

The UFMini Single-Use Tubular Bowl Centrifuge was evaluated across six independent runs to assess its ability to harvest, wash, and concentrate MSCs. Under scenario 1, the system achieved an average recovery of 93% with only 1% viability loss. Under scenario 2, recovery remained high at 94% with negligible additional loss, demonstrating robust performance across processing speeds. Under scenario 3, the system maintained strong recovery at 90%, though viability loss increased to 8%, indicating that very high flow rates can lead to breakthrough. Together, these results as seen in Figure 1 show that the UFMini supports optimal recovery and preservation of viability.

.png?sfvrsn=c049817f_1)

Figure 1: Effect of Flow Rate on Cell Recovery Compared to Incumbent

Technology Comparison

Compared to incumbent harvesting methods, which often suffer from high variability and cell quality loss due to shear exposure and manual handling, the UFMini demonstrated consistently superior outcomes. Legacy processes typically yield ~60% viable recovery, with ~20% unrecovered cells and an additional ~20% lost due to cell death. In contrast, the UFMini delivered >90% viable recovery across tested flow rates, with total cell loss (unrecovered plus damaged) as low as 6–7% and 10% at the more aggressive condition. These findings highlight the UFMini’s ability to achieve reproducible, closed-system processing that not only improves recovery efficiency but also preserves cell quality better than conventional approaches.

Scalability and Process Reliability

The UFMini demonstrated consistent performance across a range of input volumes (1-5 L) and cell densities, with no significant variation in recovery or viability. Processing times remained well within target thresholds, with 4 L processed in under 30 minutes. To evaluate scalability, a process model was developed to correlate processing time, working volume, and throughput. This model incorporated key parameters including scaled flow rates, washing and recovery conditions, and total processing time per run to extrapolate to larger volumes up to 80L. Based on this process model, it is predicted that 20 L could be processed in under 40 minutes while 80 L could be processed in under 90 minutes. These results support the feasibility of scaling to manufacturing volumes using the UniFuge Pilot (UFPilot).

Washing Protocols and Recovery

Both washing protocols maintained high cell viability and recovery exceeding the target values. Although quantitative washing efficiency was not reported, the consistent recovery outcomes suggest that the UFMini’s automated wash cycles are effective and adaptable to different process needs.

Discussion

The primary objective of this study was to evaluate the UFMini’s ability to meet end-user defined targets for MSC recovery, viability, and processing time. Compared to the incumbent process, which consistently underperformed in recovery and viability, the UFMini demonstrated significantly improved outcomes across all tested conditions.

Cell Recovery and Viability

High cell recovery is essential for the economic and therapeutic viability of MSC-based therapies. In this study, the UFMini consistently exceeded the end-user’s recovery and viability targets, outperforming the incumbent method by a substantial margin. The ability to achieve an average of 92% cell recovery and 3% cell viability loss across varying flow rates and input volumes directly supports process reliability and performance.

Scalability

As MSC-based therapies progress from process development to commercial manufacturing, scalability and reproducibility are critical. The UFMini demonstrated consistent performance across input volumes 1–5 L, with processing times under 30 minutes at 4 L, with no significant variation in recovery or viability. These results support the modeled scale-up to 80 L using the UF Pilot system, with projected processing times under 90 minutes.

Achieving Targeted Concentrations to Maximize Downstream Efficiency

At the 4 L scale, the UFMini enabled volume reductions of up to 13-fold, concentrating to as low as 300 mL. Utilizing the process modeling, the concentration expected at 80 L scale would be 44-fold.

Given the increasing need for consistent, scalable, and GMP-compliant MSC processing solutions, the UFMini and UFPilot present as strong options for both pilot and manufacturing-scale operations. Future studies are needed to confirm modeled performance at scale, further supporting the transition from development to commercial-scale production.

Conclusion

As mesenchymal stem cell (MSC) therapies continue to advance towards clinical and commercial adoption, the need for high-performance, scalable, and closed-system downstream processing solutions becomes increasingly critical. This study demonstrated that the UFMini Single-Use Tubular Bowl Centrifuge consistently delivers high cell recovery, minimal viability loss, and effective processing times across a range of flow rates and other critical process parameters.

Unlike traditional open centrifugation and semi-automated membrane filtration, the UFMini maintained reproducible outcomes through its low-shear, automated and closed-system design. This mechanistic advantage enabled recovery yields exceeding 90% and viability losses below 5%, even as flow rates and input volumes varied. These results directly support key manufacturing goals, including dose reliability, cost efficiency, and optimal use of starting material.

The system’s ability to process up to 4 L in under 30 minutes, with modeled scalability to 80 liters using the UFPilot, demonstrates its suitability into GMP-compliant workflows. The UniFuge’s capacity to preserve single-cell morphology, maintain high yield with minimal impact to viability, and support volume reduction to high-density outputs further reinforces its role in efficient, high-quality manufacturing.

Overall, the UFMini offers a reliable and efficient platform for MSC harvest, wash, and concentration, enabling a streamlined transition from early-stage development to commercial-scale manufacturing while meeting the performance expectations of modern cell therapy production.